BOBST is the world’s leading supplier of machinery and services to packaging manufacturers in the folding carton, corrugated board and flexible material industries. Founded in 1890 by Joseph Bobst in Lausanne, Switzerland, BOBST has a presence in more than 50 countries.

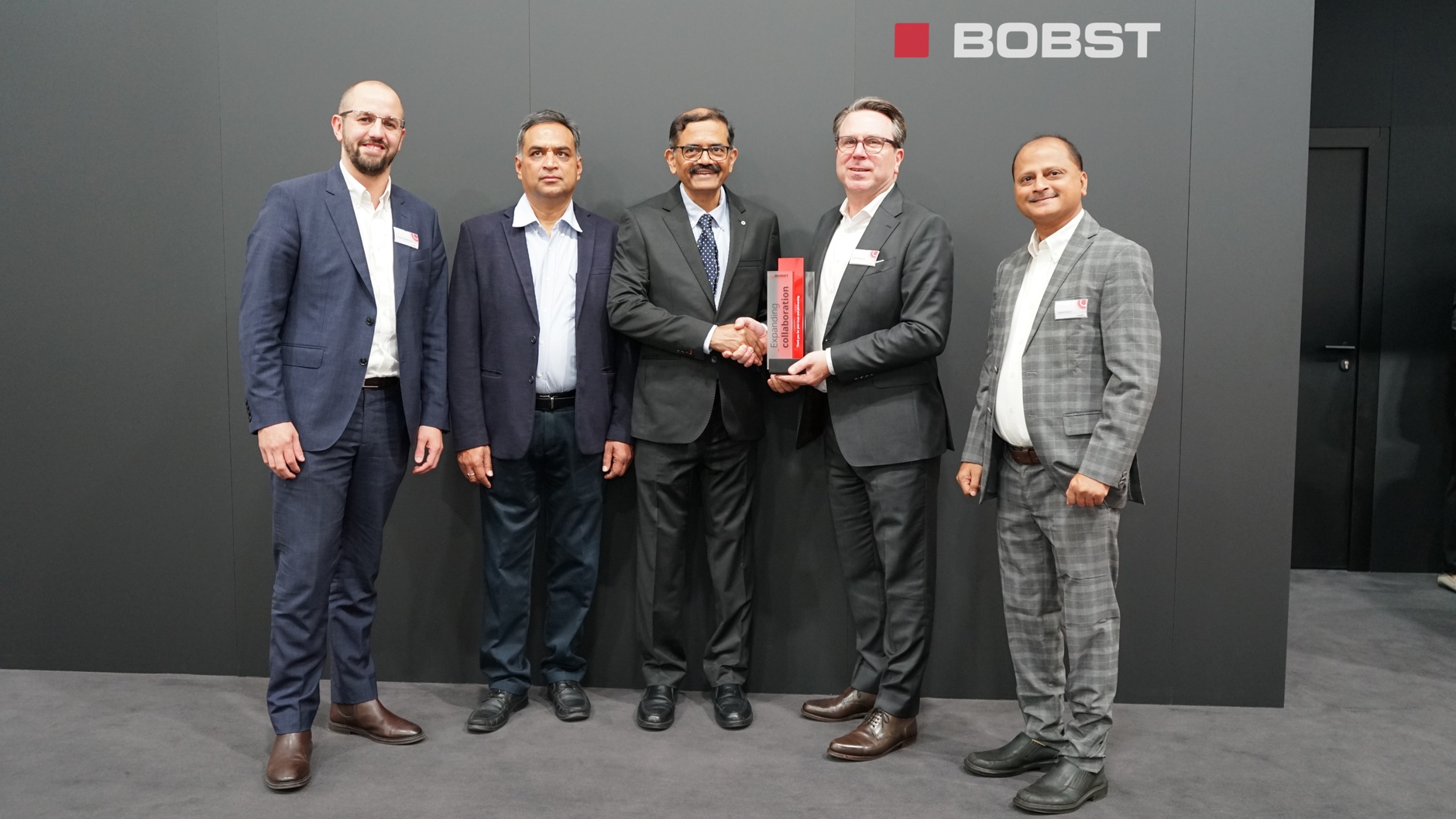

In a strategic move that underlines Toppan Speciality Films’ commitment to innovation and excellence, the company has announced a significant investment in BOBST technology.

The investment includes the acquisition of three additional BOBST EXPERT K5 Metallizers to be delivered over the next 12 months, marking a substantial expansion of Toppan’s production capabilities.

Austrian packaging manufacturer packit! serves the food industry with high-quality offset laminated corrugated board solutions. Operating out of one of the most modern production facilities in Europe, the specialist in E flute, F flute, and laminated double wall materials, has recently invested in a complete MASTERCUT 1.65 PER die-cutting line.

Today, packit! boasts an experienced team, two automated warehouses with a capacity of 53,000 pallets guaranteeing extremely short delivery times, and a suite of state-of-the-art die-cutting equipment from BOBST. But 23 years ago, the idea to found packit! only started thanks to a discussion at a coffee dispenser.

The Austrian packaging manufacturer packit! boasts a production hall full of BOBST machines and shows, how modern converting with flexible high-tech equipment leads to an efficient packaging production.

What is the solution to tackling short deadlines? Specialised in E-flute, F-flute and laminated materials, packit! in Austria has invested in a fully automatic warehouse with a capacity of 53.000 palettes to cut down delivery times to a minimum. However, the company is also able to produce e-commerce boxes from paper web to pallet ready for transport within 36 hours, thanks to the efficiency of its production.

BOBST, one of the world's leading suppliers of equipment and services for packaging and label manufacturers, announced today that it has entered into a strategic partnership with PACKITOO, a French company developing digital solutions in the packaging industry. PACKITOO’s HIPE is a web-based sales tool tailored for the packaging industry, automating quotations, managing packaging projects, and supporting web-to-pack e-shops for printers and converters.

This partnership aligns with BOBST's strategy to digitalize and connect the entire packaging value chain, from brand owners to converters and equipment suppliers. It will allow BOBST to provide printers and converters with a tailored solution, streamlining their sales cycles, reducing costs, and boosting revenues. PACKITOO will also benefit from BOBST's global presence, expertise, and network, enabling it to reach new markets and customers.

During Chinaplas 2024, over 100 customers and over 40 companies from across Southeast Asia, such as Thailand, Indonesia, Malaysia, the Philippines, Vietnam, India, and South Korea, visited the Bobst Changzhou Competence Center in Changzhou JiangSu, to experience live demonstrations of the new technologies and functionalities of the NOVA RS 5003 gravure printing machine and the NOVALAM 800 multi-technology laminator, SX 550 Laminator, and more.

BOBST Southeast Asia Pacific customer demo days at Bobst Changzhou during Chinaplas

As one of the world’s leading suppliers of substrate processing, printing, and converting equipment and services for the label, flexible packaging, folding carton, and corrugated industries, BOBST embraces the industry vision of "shaping the future of the packaging world." By actively responding to the sustainable development needs of the flexible packaging industry, BOBST is committed to providing innovative technologies and solutions that help customers improve production efficiency, reduce costs, enhance product quality, and achieve sustainability goals.

QuaLabels in Ethiopia has acquired a BOBST shaftless gravure printing press to expand its business and deliver world-class labels and packaging to local and global brand owners in the beer, soft drinks, snacks, personal care and home care markets. The strategic investment with BOBST is not only distinguishing QuaLabels from local competitors but also paving the way for growth in a challenging climate.

In realizing its vision, QuaLabels Manufacturers Plc has installed the first BOBST gravure press in Ethiopia. In fact, the new company’s machine is the first of its kind from any European manufacturer, a testament to the mission to “be the most trusted and reliable local partner with outstanding customer service and on-time delivery, at the most competitive price.”

The folding carton industry never stops evolving and shifting, and BOBST, a pioneering force in folding and gluing technology since the 1940s, has recently enhanced its folder-gluer equipment portfolio with the introduction of new generation folder-gluers for its EXPERTFOLD, VISIONFOLD and NOVAFOLD.

Responding to the changing needs of carton converters in a competitive global market, BOBST leads the industry by offering one of the most comprehensive folder-gluing line backed by global service and support. Always responsive to industry trends to ensure accessible performance at every step of production, BOBST invests heavily in research and development, evolving modular production lines and peripherals.

Chicago-based M&R Label has chosen a BOBST DIGITAL MASTER 340 All-in-One label press to better meet customer demands for quick delivery and shorter print runs. The new 100 m/min press is set make a big impact on the US company, which already serves the broadest spectrum of industries with custom product label solutions, printed flexo and digital.

A family-owned label printing company, M&R Label is managed by co-owners Steve Brownstone and Ross Samotny. Started in 1989, the business has built a great reputation on integrity, honesty, and loyalty with the promise to always put the customer first. Over 20 million labels are shipped each week from the company’s 22,000 sq. ft. facility, reaching customers from small start-ups to large brand owners and retailers across North America.

Sustainability is a key pillar for BOBST to achieve our vision of shaping the future of the packaging world, and to support our customers in achieving their goals. The Bobst Group has taken important actions on sustainability and will continue to report publicly along the strictest Environmental, Social & Governance (ESG) standards.

In 2021, we established our baseline with an initial evaluation performed by Ecovadis -– the world’s largest and most trusted provider of business sustainability ratings.

The new BOBST Competence Center, an innovation hub for the US market, is scheduled to open its doors on April 15–16, 2024. At this event, visitors will gain valuable insights into the future of label and flexible packaging production through live demos, presentations from industry experts, and exclusive networking opportunities.

The new Competence Center will provide converters and brand owners with the chance to experience BOBST’s pioneering solutions for packaging production firsthand. The new facility will be around five times larger than the previous demo center in Alpharetta, Atlanta (GA). Notably, it will feature BOBST’s flexo, digital, and all-in-one printing – as well as laminating – technologies for both flexible packaging and labels, helping to unlock new potential for printers.